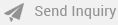

Sodium Feldspar for Ceramics Industry

Product Details:

- Hardness 6-6.5 Mohs

- Purity 90-98% (Typical for ceramics grade)

- Strength High mechanical strength

- Product Type Industrial Mineral Raw Material

- Material Sodium Feldspar (NaAlSi3O8)

- Alloy Not applicable (single mineral)

- Shape Granules or Powder

- Click to View more

Sodium Feldspar for Ceramics Industry Price And Quantity

- 21 ,

- 100 INR/Metric Ton

Sodium Feldspar for Ceramics Industry Product Specifications

- <1% (as supplied)

- Industrial Mineral Raw Material

- White to off-white

- 90-98% (Typical for ceramics grade)

- Custom granule sizes or powder as per requirement

- 6-6.5 Mohs

- High mechanical strength

- Ceramic tiles, sanitary ware, tableware, glass manufacturing

- Granules or Powder

- Sodium Feldspar (NaAlSi3O8)

- Na2O: 6-11%, Al2O3: 16-19%, SiO2: 66-69%, Fe2O3: <0.1%

- Not applicable (single mineral)

Sodium Feldspar for Ceramics Industry Trade Information

- MUNDRA PORT

- 500 , Per Month

- 10 - 15 Days

- Yes

- Free samples available with shipping and taxes paid by the buyer

- 25 Kg HDPE Bags, 50 Kg HDPE Bags, JUMBO Bags or as per the Customer's requirement

- ISO 9001:2015 Certificate D&B Certificate

Product Description

We are dedicatedly involved in offering a wide assortment of Sodium Feldspar for Ceramics Industry. Free from impurities, desirable hardness and environment friendly are qualities of offered products. In addition to this, our products are getting huge appreciation amongst our clients for their brilliant qualities. Besides, the provided Sodium Feldspar for Ceramics Industry can be availed by our client at industry leading prices. Owing to their purity and quality, these products are also used innumerous industries.

Technical Specification

| State | Powdered |

| Grade | Ceraspar 201 |

| Packaging Type | HDPE Bags, Packet |

| Packaging Size | 25Kg / 50Kg |

| Color | White |

| Purity | 7 -8 % Na2O |

| Brand Name | MULTI MINERALS INDUSTRIES |

| Dimension | 200 Mesh |

| Design Method | Glazing |

| Usage | Interior Decor, Exterior Decor, Industrial Use, Promotional Use |

| Quantity per Pack | 50 Kg HDPE Bags, Jumbo Bags |

Exceptional Flux Material for Ceramics

Sodium Feldspar acts as a primary flux in ceramic glazes and bodies, facilitating a superior melting process at lower temperatures. Its unique composition (Na2O, Al2O3, SiO2) allows for efficient vitrification, which leads to increased strength, smoothness, and whiteness in finished ceramic products.

Wide Range of Applications

Highly valued in the ceramics sector, sodium feldspar is indispensable for producing tiles, sanitary ware, and tableware. Manufacturers often favor it not just for its technical properties but also for its availability in custom granule sizes and powder, making it versatile for various production processes.

FAQs of Sodium Feldspar for Ceramics Industry:

Q: How is sodium feldspar used in the ceramics industry?

A: Sodium feldspar serves as a flux in the ceramics industry, lowering the melting point of ceramic mixtures during firing. This property enables efficient sintering and formation of strong, durable products such as tiles, sanitary ware, and tableware.Q: What benefits does sodium feldspar provide in ceramic manufacturing?

A: Benefit-wise, sodium feldspar offers high mechanical strength, excellent whiteness after firing, and improved vitrification. Its low iron content ensures minimal discoloration, leading to aesthetically pleasing and high-quality ceramic finishes.Q: Where does the whiteness range of 7090% after firing apply?

A: The whiteness range of 7090% is measured after the firing process and can vary according to the mineral deposit source. This high whiteness is preferred in applications where a bright, clean ceramic finish is required.Q: When is sodium feldspar most efficiently utilized during ceramic production?

A: Sodium feldspar is most efficiently utilized during the firing phase, typically at temperatures between 11001250C. This is when its fluxing properties aid in forming a robust, vitrified ceramic matrix.Q: What is the typical chemical composition of sodium feldspar for ceramics?

A: Ceramics-grade sodium feldspar typically contains Na2O (611%), Al2O3 (1619%), SiO2 (6669%), and very low Fe2O3 (<0.1%), ensuring high purity and suitability for white or off-white ceramic products.Q: How does sodium feldspar affect the mechanical strength of ceramics?

A: The use of sodium feldspar improves the mechanical strength of ceramic bodies by promoting uniform vitrification, leading to denser and more resilient finished products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Feldspar Powder' category

|

MULTI MINERALS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese